COMPANY

Jiangsu HongBen Industrial Components Co.,Ltd.

Jiangsu HongBen Industrial Parts Co., Ltd. (formerly Taizhou Hongben Auto Parts Co., Ltd. Drive Shaft Division), located in Xiangsheng Industrial Park, Xiangshui Industrial Economic Zone, is a manufacturer specializing in the production of front axle shafts and drive shafts for automobile chassis.

The company always adheres to the quality policy of “pragmatic innovation, quality first, customer first, sustainable development”, and adheres to the business purpose of “customer-centered” for production and sales services, and enjoys a high reputation among new and old customers.

The company sincerely welcomes merchants at home and abroad to visit and negotiate business. On the principle of equality and mutual benefit, it is willing to establish long-term cooperative relations with domestic and foreign trading partners, work together and create brilliance.

Factory area

Company employees

The drive shaft factory produces 200,000 drive shafts per year.

Production Process

In order to ensure production efficiency and improve product accuracy,

the company has also introduced all necessary inspection equipment, such as hot and cold shock testing machines, programmable sand and dust test chambers, precision high temperature chambers, etc.

In order to ensure product development and quality, the company has introduced a variety of R&D

verification equipment to ensure that the product can be fully tested and verified at the beginning of development and to ensure the stability of the product structure.

01

Incoming Material Inspection Area

02

Measuring Chamber

03

Raw Material Warehouse

04

Machining Line

05

Ultrasonic Automatic Cleaning Line

06

Self-Manufactured Parts Warehouse

07

Installation Workshop

08

Automatic Painting Line

09

Packaging Material Warehouse and Finished Product Warehouse

01

Incoming Material Inspection Area

All materials entering the factory must pass inspection before being circulated within the facility.

02

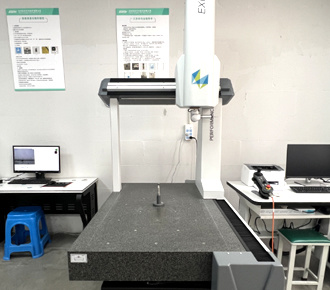

Measuring Chamber

Key components undergo metallographic and physicochemical analysis.

03

Raw Material Warehouse

Different materials are managed precisely in separate warehouses, organized according to lean management principles.

04

Machining Lfine

Self-manufactured parts are processed using single-clamping, multi-process centralized machining to reduce errors from repeated clamping and unnecessary waste from process turnover, thereby improving product input-output efficiency.

05

Ultrasonic Automatic Cleaning Line

Depending on the actual production scenario, there are two selectable modes: "cleaning and rust prevention" or "cleaning and drying."

06

Self-Manufactured Parts Warehouse

Standard racks, pallets, and turnover boxes are utilized, with self-manufactured parts precisely managed according to the first-in, first-out principle.

07

Installation Workshop

A 2000-square-meter dust-free workshop, featuring dual backups for core equipment and 100% online inspection of key processes, ensures stable and reliable production progress and quality.

08

Automatic Painting Line

By combining pre-treatment, electrostatic painting, leveling, and baking in one seamless process, the use of a conveyor chain ensures continuity, consistency, and efficiency in product painting.

09

Packaging Material Warehouse and Finished Product Warehouse

To meet diverse market and customer requirements, inventory agility is maximized for both finished products and packaging materials, ensuring user demands are met promptly.

Technical Team

We have a professional technical R&D team, with 8 product R&D personnel, 3 engineers (including 2 masters), 3 people with automotive professional background, and 2 senior GKN experts employed on a long-term basis. Possessing the ability to “synchronize design, development and analysis with vehicle manufacturers”. And the annual investment in R&D accounts for more than 5% of sales.

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Sales Network

Hongben has gained wide domestic and international market acceptance and reliable credibility with its advanced production technology, exquisite process flow, excellent product quality and sincere after-sales service.

United States

Canada

Colombia

Mexico

Brazil

Australia

Germany

United Kingdom

Italy

Iran

Thailand

Japan

Partners

Planning and The Future

We will forge ahead with the times with our love for the auto parts industry, our pursuit of excellent quality, and our persistence in innovative research and development. Looking to the future, the curtain of a new journey has begun. Hongben will open up a broader horizon and embrace new opportunities and challenges.

Innovation is the eternal proposition of the times.

Products are the best image of an enterprise.

The love for the auto part industry

The pursuit of excellent quality

The persistence in innovative R&D